![]() Yiba nomfanekiso wendlela yokwenza izinto apho kungekho nto imoshayo, inyathelo ngalinye lenza imveliso ibengcono, kwaye usebenzisa zonke izixhobo zakho ngobulumko. Lo ngundoqo wokwenziwa kwemveliso. Ukuba ukhe wazibuza ukuba ezinye iinkampani zikwazi njani ukuvelisa ngakumbi ngokuncinci, sele uzakufumana iimfihlo. Kule blog post, siza kuhlola

Yiba nomfanekiso wendlela yokwenza izinto apho kungekho nto imoshayo, inyathelo ngalinye lenza imveliso ibengcono, kwaye usebenzisa zonke izixhobo zakho ngobulumko. Lo ngundoqo wokwenziwa kwemveliso. Ukuba ukhe wazibuza ukuba ezinye iinkampani zikwazi njani ukuvelisa ngakumbi ngokuncinci, sele uzakufumana iimfihlo. Kule blog post, siza kuhlola ![]() imigaqo emi-5 engundoqo yokwenziwa kwemveliso ebhityileyo

imigaqo emi-5 engundoqo yokwenziwa kwemveliso ebhityileyo![]() , kukuthatha kuhambo ngendlela eye yanceda amashishini amaninzi kwihlabathi liphela.

, kukuthatha kuhambo ngendlela eye yanceda amashishini amaninzi kwihlabathi liphela.

Isiqulatho

Isiqulatho

Yintoni Imveliso Ebhityileyo?

Yintoni Imveliso Ebhityileyo? IiNzuzo zeMveliso ebhityileyo

IiNzuzo zeMveliso ebhityileyo ImiGaqo emi-5 yeMveliso eBonelekileyo

ImiGaqo emi-5 yeMveliso eBonelekileyo Iingcinga Final

Iingcinga Final Ii-FAQs Malunga neMithetho-siseko yokuVelisa okuBonke

Ii-FAQs Malunga neMithetho-siseko yokuVelisa okuBonke

Yintoni Imveliso Ebhityileyo?

Yintoni Imveliso Ebhityileyo?

Umfanekiso: freepik

Umfanekiso: freepik![]() Imveliso ebhityileyo yindlela ecwangcisiweyo yokuvelisa, ejolise ekunciphiseni inkunkuma, ukwandisa ukusebenza kakuhle, nokubonelela ngexabiso kubathengi. Le ndlela yavela kwi

Imveliso ebhityileyo yindlela ecwangcisiweyo yokuvelisa, ejolise ekunciphiseni inkunkuma, ukwandisa ukusebenza kakuhle, nokubonelela ngexabiso kubathengi. Le ndlela yavela kwi ![]() Inkqubo yeMveliso yeToyota (TPS)

Inkqubo yeMveliso yeToyota (TPS)![]() kwaye ngoku yamkelwe kwihlabathi jikelele ngamashishini ahlukeneyo kunye namashishini.

kwaye ngoku yamkelwe kwihlabathi jikelele ngamashishini ahlukeneyo kunye namashishini.

![]() Eyona njongo iphambili yemveliso ebhityileyo kukwenza lula inkqubo yemveliso ngokuchonga nokususa nayiphi na imisebenzi engeyomfuneko, imathiriyeli, okanye izixhobo ezingenagalelo ngokuthe ngqo kwimveliso okanye inkonzo yokugqibela. Oku kunceda ukulungelelanisa inkqubo kwaye yenze isebenze ngakumbi.

Eyona njongo iphambili yemveliso ebhityileyo kukwenza lula inkqubo yemveliso ngokuchonga nokususa nayiphi na imisebenzi engeyomfuneko, imathiriyeli, okanye izixhobo ezingenagalelo ngokuthe ngqo kwimveliso okanye inkonzo yokugqibela. Oku kunceda ukulungelelanisa inkqubo kwaye yenze isebenze ngakumbi.

IiNzuzo zeMveliso ebhityileyo

IiNzuzo zeMveliso ebhityileyo

![]() Imveliso ebhityileyo ibonelela ngeenzuzo ezininzi kwiinkampani ezijolise ekuphuculeni imisebenzi yazo. Nazi iingenelo ezintlanu eziphambili:

Imveliso ebhityileyo ibonelela ngeenzuzo ezininzi kwiinkampani ezijolise ekuphuculeni imisebenzi yazo. Nazi iingenelo ezintlanu eziphambili:

Ukugcina iindleko

Ukugcina iindleko : Imveliso ebhityileyo ichonga kwaye ishenxise inkunkuma kwiinkqubo, ngaloo ndlela inciphisa iindleko zokusebenza. Oku kunokubandakanya iindleko eziphantsi ze-inventri, ukunciphisa ukusetyenziswa kwamandla, kunye nokusebenza okuncinci, ekugqibeleni ukwandisa inzuzo yenkampani.

: Imveliso ebhityileyo ichonga kwaye ishenxise inkunkuma kwiinkqubo, ngaloo ndlela inciphisa iindleko zokusebenza. Oku kunokubandakanya iindleko eziphantsi ze-inventri, ukunciphisa ukusetyenziswa kwamandla, kunye nokusebenza okuncinci, ekugqibeleni ukwandisa inzuzo yenkampani. Yandisa ukusebenza kakuhle:

Yandisa ukusebenza kakuhle: Ngokuhlengahlengisa iinkqubo, ukuphelisa imiqobo, kunye nokwandisa ukuhamba komsebenzi, ukuvelisa okubhityileyo kwandisa ukusebenza kakuhle. Oku kuthetha ukuba amashishini anokuvelisa ngaphezulu ngesixa esifanayo sezibonelelo okanye ngaphantsi, efumana okuninzi kutyalo-mali lwawo.

Ngokuhlengahlengisa iinkqubo, ukuphelisa imiqobo, kunye nokwandisa ukuhamba komsebenzi, ukuvelisa okubhityileyo kwandisa ukusebenza kakuhle. Oku kuthetha ukuba amashishini anokuvelisa ngaphezulu ngesixa esifanayo sezibonelelo okanye ngaphantsi, efumana okuninzi kutyalo-mali lwawo.  Umgangatho ophuculweyo:

Umgangatho ophuculweyo:  Imveliso ebhityileyo igxile ekuchongeni nasekusombululeni oonobangela beziphene, ezikhokelela kumgangatho ophezulu wemveliso. Oku kuthetha iimpazamo ezimbalwa, ukulungiswa okuncinci, kunye nokwaneliseka okungcono kwabathengi.

Imveliso ebhityileyo igxile ekuchongeni nasekusombululeni oonobangela beziphene, ezikhokelela kumgangatho ophezulu wemveliso. Oku kuthetha iimpazamo ezimbalwa, ukulungiswa okuncinci, kunye nokwaneliseka okungcono kwabathengi. Ukuhanjiswa ngokukhawuleza:

Ukuhanjiswa ngokukhawuleza:  Izenzo ezibhityileyo zikhokelela kumaxesha amafutshane okukhokela kunye nokuphendula ngokukhawuleza kwiimfuno zabathengi. Ukukwazi ukuvelisa kunye nokuhambisa iimveliso ngexesha kunokunceda iinkampani zifumane inzuzo yokhuphiswano kwaye zihlangabezane nokulindelwe ngabathengi.

Izenzo ezibhityileyo zikhokelela kumaxesha amafutshane okukhokela kunye nokuphendula ngokukhawuleza kwiimfuno zabathengi. Ukukwazi ukuvelisa kunye nokuhambisa iimveliso ngexesha kunokunceda iinkampani zifumane inzuzo yokhuphiswano kwaye zihlangabezane nokulindelwe ngabathengi. Ukwandisa ukuzibandakanya kwabasebenzi:

Ukwandisa ukuzibandakanya kwabasebenzi:  Imigaqo ebhityileyo ikhuthaza ukubandakanyeka kwabasebenzi, ukusonjululwa kweengxaki, kunye nokuxhotyiswa. Abasebenzi ababandakanyekayo bayakhuthazeka ngakumbi, nto leyo ekhokelela kwindawo esebenza kakuhle ngakumbi kunye nokuphuculwa okuqhubekayo.

Imigaqo ebhityileyo ikhuthaza ukubandakanyeka kwabasebenzi, ukusonjululwa kweengxaki, kunye nokuxhotyiswa. Abasebenzi ababandakanyekayo bayakhuthazeka ngakumbi, nto leyo ekhokelela kwindawo esebenza kakuhle ngakumbi kunye nokuphuculwa okuqhubekayo.

ImiGaqo emi-5 yeMveliso eBonelekileyo

ImiGaqo emi-5 yeMveliso eBonelekileyo

ImiGaqo emi-5 yeMveliso eBonelekileyo. Umfanekiso: Iplanethi Kunye

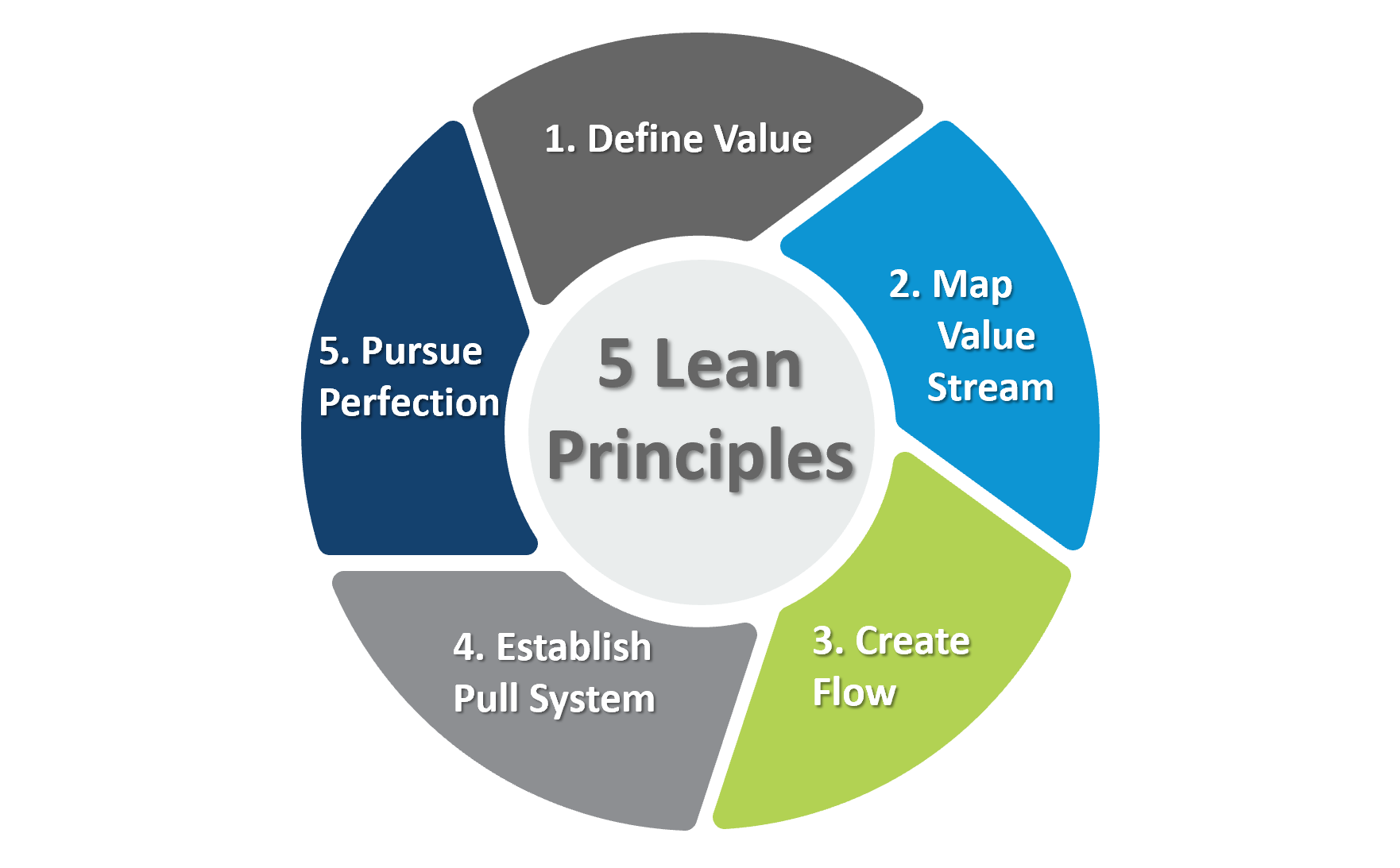

ImiGaqo emi-5 yeMveliso eBonelekileyo. Umfanekiso: Iplanethi Kunye![]() Yeyiphi imigaqo emi-5 yokwenziwa kweLean? Imigaqo emihlanu engundoqo yokwenziwa kwemveliso ebhityileyo yile:

Yeyiphi imigaqo emi-5 yokwenziwa kweLean? Imigaqo emihlanu engundoqo yokwenziwa kwemveliso ebhityileyo yile:

I-1/ Ixabiso: Ukubonelela ngezinto ezibalulekileyo kuMthengi

I-1/ Ixabiso: Ukubonelela ngezinto ezibalulekileyo kuMthengi

![]() Umgaqo wokuqala we-Lean Manufacturing kukuqonda kunye nokuhambisa "Ixabiso". Lo mbono ujikeleza ekuchongeni ngokucacileyo oko abathengi bakuxabisa ngokwenene kwimveliso okanye kwinkonzo. Imbono ye-Lean yexabiso kumthengi-centric ukuchonga iimpawu ezithile, iimpawu, okanye iimpawu apho abathengi bazimisele ukuhlawula. Nantoni na engenagalelo kwezi zinto zixabisekileyo igqalwa njengenkunkuma.

Umgaqo wokuqala we-Lean Manufacturing kukuqonda kunye nokuhambisa "Ixabiso". Lo mbono ujikeleza ekuchongeni ngokucacileyo oko abathengi bakuxabisa ngokwenene kwimveliso okanye kwinkonzo. Imbono ye-Lean yexabiso kumthengi-centric ukuchonga iimpawu ezithile, iimpawu, okanye iimpawu apho abathengi bazimisele ukuhlawula. Nantoni na engenagalelo kwezi zinto zixabisekileyo igqalwa njengenkunkuma.

![]() Ukuqonda “ixabiso” kubandakanya ukulungelelanisa ngokusondeleyo imisebenzi yeshishini nezinto ezilindelwe ngabathengi kunye neemfuno. Ngokuqonda ukuba abathengi bafuna ntoni ngokwenene, umbutho unokwalathisa izixhobo kunye neenzame zawo ekuhambiseni kanye oko kongeza ixabiso, ngelixa unciphisa okanye ususa amacandelo angongezi xabiso. Le ndlela yokufundisa iqinisekisa ukuba izibonelelo zabiwa ngokufanelekileyo, nto leyo engumba ongundoqo weMimiselo ye-Lean Manufacturing.

Ukuqonda “ixabiso” kubandakanya ukulungelelanisa ngokusondeleyo imisebenzi yeshishini nezinto ezilindelwe ngabathengi kunye neemfuno. Ngokuqonda ukuba abathengi bafuna ntoni ngokwenene, umbutho unokwalathisa izixhobo kunye neenzame zawo ekuhambiseni kanye oko kongeza ixabiso, ngelixa unciphisa okanye ususa amacandelo angongezi xabiso. Le ndlela yokufundisa iqinisekisa ukuba izibonelelo zabiwa ngokufanelekileyo, nto leyo engumba ongundoqo weMimiselo ye-Lean Manufacturing.

I-2/ I-Value Stream Mapping: Ukubona ukuHamba komsebenzi

I-2/ I-Value Stream Mapping: Ukubona ukuHamba komsebenzi

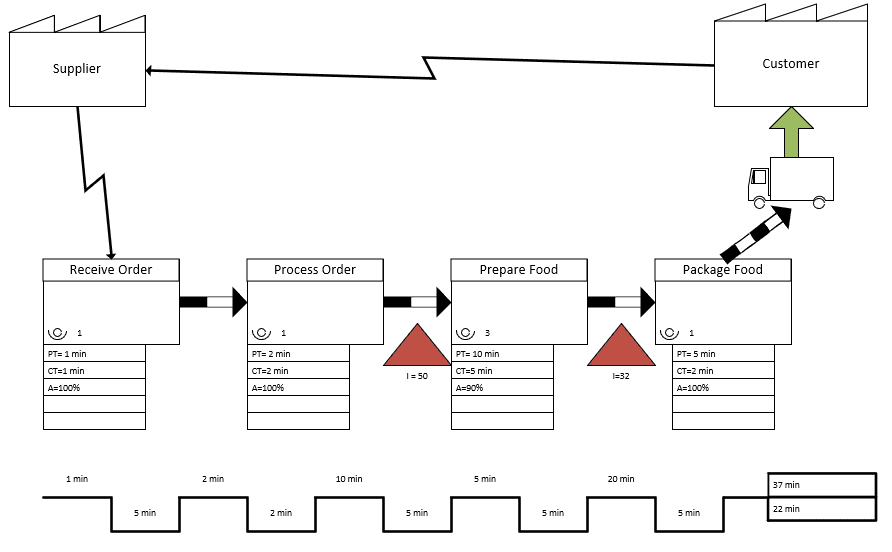

![]() Umgaqo wesibini we-Lean, "I-Value Stream Mapping," idlala indima ebalulekileyo ekuncedeni imibutho ibone kwaye isuse inkunkuma kwiinkqubo zayo.

Umgaqo wesibini we-Lean, "I-Value Stream Mapping," idlala indima ebalulekileyo ekuncedeni imibutho ibone kwaye isuse inkunkuma kwiinkqubo zayo.

![]() Imephu yexabiso lomsinga ibandakanya ukubonakaliswa okubonakalayo okubanzi kwayo yonke inkqubo, ukusuka kwimvelaphi yemathiriyeli ekrwada ukuya kwimveliso yokugqibela okanye inkonzo enikiweyo. Oku kubonwa kunceda ekuqondeni ukulandelelana kwemisebenzi ebandakanyekayo kwinkqubo.

Imephu yexabiso lomsinga ibandakanya ukubonakaliswa okubonakalayo okubanzi kwayo yonke inkqubo, ukusuka kwimvelaphi yemathiriyeli ekrwada ukuya kwimveliso yokugqibela okanye inkonzo enikiweyo. Oku kubonwa kunceda ekuqondeni ukulandelelana kwemisebenzi ebandakanyekayo kwinkqubo.

![]() Imephu yexabiso lomsinga sisixhobo esibalulekileyo sokwahlula phakathi kwemisebenzi enegalelo kwixabiso kwimveliso okanye kwinkonzo naleyo ingenalo. Imisebenzi engeyongeza ixabiso, edla ngokubizwa ngokuba yi-"muda", inokubandakanya iindlela ezahlukeneyo zenkunkuma, ezinjengokuvelisa ngokugqithisileyo, uluhlu lwezinto ezininzi, ixesha lokulinda, kunye nokusetyenzwa ngokungeyomfuneko.

Imephu yexabiso lomsinga sisixhobo esibalulekileyo sokwahlula phakathi kwemisebenzi enegalelo kwixabiso kwimveliso okanye kwinkonzo naleyo ingenalo. Imisebenzi engeyongeza ixabiso, edla ngokubizwa ngokuba yi-"muda", inokubandakanya iindlela ezahlukeneyo zenkunkuma, ezinjengokuvelisa ngokugqithisileyo, uluhlu lwezinto ezininzi, ixesha lokulinda, kunye nokusetyenzwa ngokungeyomfuneko.

![]() Ngokuchonga nokuphelisa le mithombo yenkunkuma, imibutho inokulungelelanisa iinkqubo zayo, inciphise amaxesha okukhokela, kwaye iphucule ukusebenza kakuhle ngokupheleleyo.

Ngokuchonga nokuphelisa le mithombo yenkunkuma, imibutho inokulungelelanisa iinkqubo zayo, inciphise amaxesha okukhokela, kwaye iphucule ukusebenza kakuhle ngokupheleleyo.

![]() Nanku umzekelo weValue Stream Mapping, enokukunceda ukuba uyiqonde ngcono:

Nanku umzekelo weValue Stream Mapping, enokukunceda ukuba uyiqonde ngcono:

Umfanekiso: Isoftware ye-BMC

Umfanekiso: Isoftware ye-BMC I-3/ Flow: Ukuqinisekisa ukuqhubela phambili ngokungenamthungo

I-3/ Flow: Ukuqinisekisa ukuqhubela phambili ngokungenamthungo

![]() "Ukuhamba" kujoliswe ekudaleni ukuhamba kakuhle nokuqhubekayo komsebenzi ngaphakathi kwintlangano. Ingcamango ye-Flow igxininisa ukuba umsebenzi kufuneka uhambe ukusuka kwinqanaba ukuya kwelinye ngaphandle kokuphazamiseka okanye ukuphazamiseka, ekugqibeleni ukhuthaze ukusebenza kakuhle.

"Ukuhamba" kujoliswe ekudaleni ukuhamba kakuhle nokuqhubekayo komsebenzi ngaphakathi kwintlangano. Ingcamango ye-Flow igxininisa ukuba umsebenzi kufuneka uhambe ukusuka kwinqanaba ukuya kwelinye ngaphandle kokuphazamiseka okanye ukuphazamiseka, ekugqibeleni ukhuthaze ukusebenza kakuhle.

![]() Ngokwembono yombutho, iLean ikhuthaza ukusekwa kwendawo yokusebenza apho imisebenzi kunye nemisebenzi ihamba ngaphandle kwemiqobo okanye ukulibaziseka.

Ngokwembono yombutho, iLean ikhuthaza ukusekwa kwendawo yokusebenza apho imisebenzi kunye nemisebenzi ihamba ngaphandle kwemiqobo okanye ukulibaziseka.

![]() Qwalasela umgca wendibano yokuvelisa njengomzekelo wokuphumeza "ukuhamba." Isitishi ngasinye senza umsebenzi othile kwaye iimveliso zihamba ngaphandle komthungo ukusuka kwesinye isikhululo ukuya kwesinye ngaphandle kokuphazamiseka. Oku kubonisa ingqikelelo ye-Flow in Lean.

Qwalasela umgca wendibano yokuvelisa njengomzekelo wokuphumeza "ukuhamba." Isitishi ngasinye senza umsebenzi othile kwaye iimveliso zihamba ngaphandle komthungo ukusuka kwesinye isikhululo ukuya kwesinye ngaphandle kokuphazamiseka. Oku kubonisa ingqikelelo ye-Flow in Lean.

I-4/ Inkqubo yokutsalwa: Ukuphendula kwiMfuno

I-4/ Inkqubo yokutsalwa: Ukuphendula kwiMfuno

![]() INkqubo yokuTsala imalunga nokuvelisa okanye ukuhambisa iinkonzo ngokuphendula imiyalelo yabathengi. Imibutho eyamkela iNkqubo yokuTsalwa ayenzi izinto ngokusekelwe kuqikelelo lwemfuno yexesha elizayo. Kunoko, baphendula kwimiyalelo yokwenyani efunyenweyo. Olu qheliselo lunciphisa ukuvelisa ngokugqithisileyo, enye ye

INkqubo yokuTsala imalunga nokuvelisa okanye ukuhambisa iinkonzo ngokuphendula imiyalelo yabathengi. Imibutho eyamkela iNkqubo yokuTsalwa ayenzi izinto ngokusekelwe kuqikelelo lwemfuno yexesha elizayo. Kunoko, baphendula kwimiyalelo yokwenyani efunyenweyo. Olu qheliselo lunciphisa ukuvelisa ngokugqithisileyo, enye ye ![]() iindlela ezisixhenxe eziphambili zenkunkuma

iindlela ezisixhenxe eziphambili zenkunkuma![]() kwimveliso ye-Lean.

kwimveliso ye-Lean.

Umzekelo wenkqubo yokutsala yivenkile enkulu. Abathengi batsala iimveliso abazifunayo kwiishelufa, kwaye ivenkile enkulu iphinda igcine iishelufu njengoko zifuneka. Le nkqubo iqinisekisa ukuba kusoloko kukho uluhlu olwaneleyo lokuhlangabezana neemfuno zabathengi, kodwa akukho mveliso igqithisileyo.

Umzekelo wenkqubo yokutsala yivenkile enkulu. Abathengi batsala iimveliso abazifunayo kwiishelufa, kwaye ivenkile enkulu iphinda igcine iishelufu njengoko zifuneka. Le nkqubo iqinisekisa ukuba kusoloko kukho uluhlu olwaneleyo lokuhlangabezana neemfuno zabathengi, kodwa akukho mveliso igqithisileyo.

Omnye umzekelo wenkqubo yokutsalwa ngumthengisi weemoto. Abathengi batsala iimoto abanomdla kuzo kwiqashiso kwaye bazithathele uvavanyo. Umthengisi uodola kuphela iimoto ezintsha kumenzi njengoko zifuneka ukuhlangabezana nemfuno yabathengi.

Omnye umzekelo wenkqubo yokutsalwa ngumthengisi weemoto. Abathengi batsala iimoto abanomdla kuzo kwiqashiso kwaye bazithathele uvavanyo. Umthengisi uodola kuphela iimoto ezintsha kumenzi njengoko zifuneka ukuhlangabezana nemfuno yabathengi.

5/ Uphuculo oluqhubekayo (eKaizen)

5/ Uphuculo oluqhubekayo (eKaizen)

Umfanekiso: freepik

Umfanekiso: freepik![]() Umgaqo wesihlanu kunye nowokugqibela we-Lean "Uphuculo oluqhubekayo," owaziwa ngokuba yi "Kaizen" okanye

Umgaqo wesihlanu kunye nowokugqibela we-Lean "Uphuculo oluqhubekayo," owaziwa ngokuba yi "Kaizen" okanye ![]() Kaizen inkqubo yokuphucula eqhubekayo

Kaizen inkqubo yokuphucula eqhubekayo![]() . Imalunga nokukhuthaza inkcubeko yokuphucula okokoko.

. Imalunga nokukhuthaza inkcubeko yokuphucula okokoko.

![]() Kubandakanya ukwenza uphuculo oluncinci, olungaguquguqukiyo ekuhambeni kwexesha kunokuba wenze utshintsho olukhulu okanye olumandla. Olu phuculo luncinci ludibanisa, lukhokelela kwinkqubela phambili ebalulekileyo kwinkqubo, umgangatho, kunye nokusebenza kakuhle.

Kubandakanya ukwenza uphuculo oluncinci, olungaguquguqukiyo ekuhambeni kwexesha kunokuba wenze utshintsho olukhulu okanye olumandla. Olu phuculo luncinci ludibanisa, lukhokelela kwinkqubela phambili ebalulekileyo kwinkqubo, umgangatho, kunye nokusebenza kakuhle.

![]() Omnye wemiba ebalulekileyo yeKaizen yindalo yayo ebanzi. Ikhuthaza ukuthatha inxaxheba kuwo onke amanqanaba ombutho, ivumela abasebenzi ukuba banikele ngeengcamango zabo, ukujonga kunye nokuqonda. Le ndlela ayiphuculi kuphela izakhono zokusombulula iingxaki kodwa ikwanyusa izinga lokuziphatha kwabasebenzi kunye nokuzibandakanya.

Omnye wemiba ebalulekileyo yeKaizen yindalo yayo ebanzi. Ikhuthaza ukuthatha inxaxheba kuwo onke amanqanaba ombutho, ivumela abasebenzi ukuba banikele ngeengcamango zabo, ukujonga kunye nokuqonda. Le ndlela ayiphuculi kuphela izakhono zokusombulula iingxaki kodwa ikwanyusa izinga lokuziphatha kwabasebenzi kunye nokuzibandakanya.

![]() UKaizen uqinisekisa ukuba umbutho uhlala ukhuthazwa ukuba ubengcono, usebenze kakuhle, kwaye usebenze ngakumbi. Kukuzibophelela ekuphuculeni okuqhubekayo kwaye ngumba osisiseko wenkcubeko ye-Lean.

UKaizen uqinisekisa ukuba umbutho uhlala ukhuthazwa ukuba ubengcono, usebenze kakuhle, kwaye usebenze ngakumbi. Kukuzibophelela ekuphuculeni okuqhubekayo kwaye ngumba osisiseko wenkcubeko ye-Lean.

Iingcinga Final

Iingcinga Final

![]() IMigaqo emi-5 yoMveliso oNcincisayo: Ixabiso, iMaphu yokuLawulwa kweXabiso, ukuMpompoza, iNkqubo yokuTsala, kunye noPhuculo oluQhubekekayo (iKaizen) - ibonelela imibutho ngesikhokelo esinamandla sokuphumeza ukugqwesa kokusebenza.

IMigaqo emi-5 yoMveliso oNcincisayo: Ixabiso, iMaphu yokuLawulwa kweXabiso, ukuMpompoza, iNkqubo yokuTsala, kunye noPhuculo oluQhubekekayo (iKaizen) - ibonelela imibutho ngesikhokelo esinamandla sokuphumeza ukugqwesa kokusebenza.

![]() Imibutho eyamkela iMigaqo ye-L5 ye-Lean Manufacturing ayiphuculi nje ukusebenza kwayo kuphela kodwa ikwanciphisa inkcitho kwaye yandise umgangatho weemveliso kunye neenkonzo zayo.

Imibutho eyamkela iMigaqo ye-L5 ye-Lean Manufacturing ayiphuculi nje ukusebenza kwayo kuphela kodwa ikwanciphisa inkcitho kwaye yandise umgangatho weemveliso kunye neenkonzo zayo.

Imibuzo ebuzwa qho

Imibuzo ebuzwa qho

Yeyiphi imigaqo emi-5 yokwenziwa kwemveliso ebhityileyo?

Yeyiphi imigaqo emi-5 yokwenziwa kwemveliso ebhityileyo?

![]() Imigaqo emi-5 yokuvelisa okubhityileyo liXabiso, iMaphu yokuLawulwa kweXabiso, ukuMpompoza, iNkqubo yokuTsalwa, kunye noPhuculo oluqhubekayo (Kaizen).

Imigaqo emi-5 yokuvelisa okubhityileyo liXabiso, iMaphu yokuLawulwa kweXabiso, ukuMpompoza, iNkqubo yokuTsalwa, kunye noPhuculo oluqhubekayo (Kaizen).

Ingaba kukho imigaqo emi-5 okanye esi-7?

Ingaba kukho imigaqo emi-5 okanye esi-7?

![]() Ngelixa kukho ukutolika okwahlukileyo, eyona migaqo i-Lean eyaziwayo kakhulu yile mi-5 ikhankanywe ngasentla.

Ngelixa kukho ukutolika okwahlukileyo, eyona migaqo i-Lean eyaziwayo kakhulu yile mi-5 ikhankanywe ngasentla.

Yeyiphi imigaqo eyi-10 yokuvelisa imveliso ebhityileyo?

Yeyiphi imigaqo eyi-10 yokuvelisa imveliso ebhityileyo?

![]() Imithetho ye-10 yemveliso ebhityileyo ayingomgangatho omiselweyo kwimveliso ye-Lean. Imigaqo ebhityileyo idla ngokusekwe kwimigaqo emi-5 engundoqo ekhankanywe ngaphambili. Eminye imithombo inokudwelisa "imithetho," kodwa akuvunyelwana ngayo jikelele.

Imithetho ye-10 yemveliso ebhityileyo ayingomgangatho omiselweyo kwimveliso ye-Lean. Imigaqo ebhityileyo idla ngokusekwe kwimigaqo emi-5 engundoqo ekhankanywe ngaphambili. Eminye imithombo inokudwelisa "imithetho," kodwa akuvunyelwana ngayo jikelele.