Cabanga ngendlela yokwenza izinto lapho kungekho okumoshayo, zonke izinyathelo zenza umkhiqizo ube ngcono, futhi usebenzisa zonke izinsiza zakho ngokuhlakanipha. Yilokho ingqikithi yokukhiqiza mafutha. Uma uke wazibuza ukuthi ezinye izinkampani zikwazi kanjani ukukhiqiza okuningi ngokuncane, usuzothola izimfihlo. Kulokhu okuthunyelwe kwebhulogi, sizohlola Izimiso ezi-5 eziwumongo zokukhiqiza okuthambile, kukuthatha ohambweni lwakho ngendlela esize amabhizinisi amaningi emhlabeni jikelele.

Okuqukethwe

- Iyini I-Lean Manufacturing?

- Izinzuzo Zokukhiqiza I-Lean

- Izimiso ezi-5 Zokukhiqiza I-Lean

- Imicabango Final

- Imibuzo Evame Ukubuzwa Ngezimiso Zokukhiqiza I-Lean

Iyini I-Lean Manufacturing?

Ukukhiqiza okunciphile kuyindlela ehlelekile yokukhiqiza, okuhloswe ngayo ukunciphisa ukumosha, ukwandisa ukusebenza kahle, nokuhlinzeka ngenani kumakhasimende. Le ndlela yasungulwa kusukela ku- I-Toyota Production System (TPS) futhi manje sesamukelwe emhlabeni wonke yizimboni namabhizinisi ahlukahlukene.

Umgomo oyinhloko wokukhiqiza okuncane ukwenza lula inqubo yokukhiqiza ngokuhlonza nokususa noma yimiphi imisebenzi engadingekile, izinto ezisetshenziswayo, noma izinsiza ezinganikeleli ngokuqondile kumkhiqizo noma isevisi yokugcina. Lokhu kusiza ukwenza lula inqubo futhi yenze isebenze kahle.

Izinzuzo Zokukhiqiza I-Lean

Ukukhiqiza okuthambile kunikeza izinzuzo ezimbalwa ezinkampanini ezihlose ukuthuthukisa ukusebenza kwazo. Nazi izinzuzo ezinhlanu ezibalulekile:

- Ukonga izindleko: Ukukhiqiza okuthambile kukhomba futhi kuqede udoti ezinqubweni, ngaleyo ndlela kunciphisa izindleko zokusebenza. Lokhu kungabandakanya izindleko eziphansi ze-inventory, ukusetshenziswa kwamandla okuncishisiwe, kanye nokusebenza kabusha okuncane, ekugcineni kwandise inzuzo yenkampani.

- Khulisa ukusebenza kahle: Ngokwenza lula izinqubo, ukuqeda izingqinamba, nokwandisa ukuhamba komsebenzi, ukukhiqiza okunciphile kwandisa ukusebenza kahle. Lokhu kusho ukuthi amabhizinisi angakhiqiza okuningi ngenani elifanayo lezinsiza noma ngaphansi, athole okuningi ekutshalweni kwawo.

- Ikhwalithi ethuthukisiwe: Ukukhiqiza okuthambile kugxile ekuhlonzeni nasekuxazululeni izimbangela zamaphutha, okuholela kwikhwalithi ephezulu yomkhiqizo. Lokhu kusho amaphutha ambalwa, ukusebenza kabusha okuncane, nokwaneliseka okungcono kwamakhasimende.

- Ukulethwa okusheshayo: Imikhuba yokuncika iholela ezikhathini zokuhola ezifushane kanye nokusabela okusheshayo ezidingweni zamakhasimende. Ikhono lokukhiqiza nokuletha imikhiqizo ngesikhathi lingasiza izinkampani zithole inzuzo yokuncintisana futhi zihlangabezane nokulindelwe ngamakhasimende.

- Khulisa ukuzibandakanya kwabasebenzi: Izimiso ezinciphile zikhuthaza ukuzibandakanya kwabasebenzi, ukuxazulula izinkinga, nokunika amandla. Abasebenzi abathenjisiwe bakhuthazeka kakhulu, okuholela endaweni enhle yokusebenza kanye nokwenza ngcono okuqhubekayo.

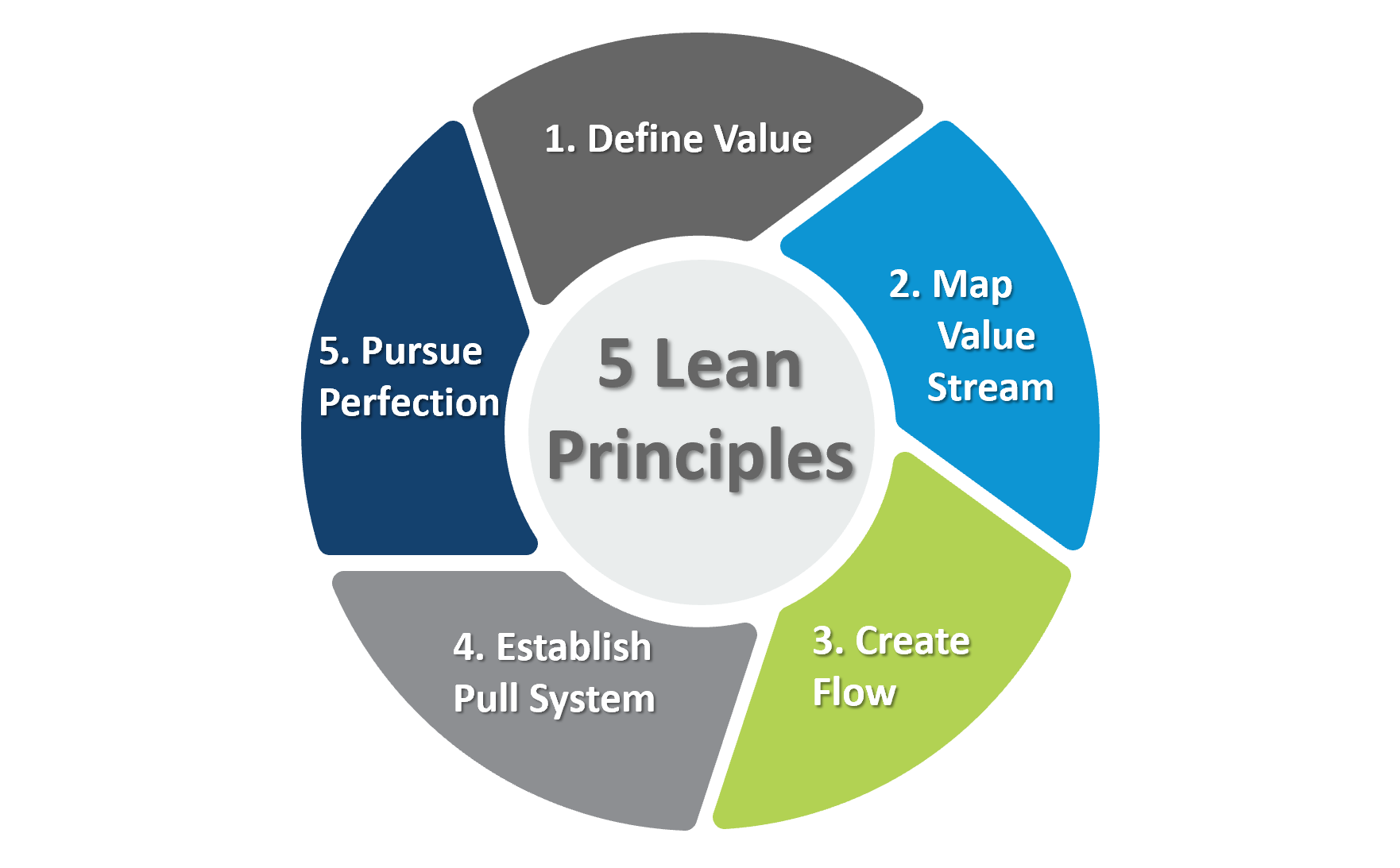

Izimiso ezi-5 Zokukhiqiza I-Lean

Yiziphi izimiso ezi-5 zokukhiqiza i-Lean? Izimiso ezinhlanu ezibalulekile zokukhiqiza okungenalutho yilezi:

I-1/ Inani: Ukunikeza Okubalulekile Ekhasimendeni

Umgomo wokuqala we-Lean Manufacturing ukuqonda nokuletha “Value”. Lo mqondo uzungeza ekuboneni ngokucacile lokho amakhasimende akwazisa ngempela kumkhiqizo noma isevisi. Umbono we-Lean wevelu ugxile kukhasimende ukukhomba izici ezithile, izimfanelo, noma izibaluli amakhasimende azimisele ukuzikhokhela. Noma yini engabambi iqhaza kulezi zakhi ezibalulekile ithathwa njengokumoshayo.

Ukubona “inani” kuhlanganisa ukuqondisa eduze imisebenzi yebhizinisi nokulindelwe yikhasimende kanye nezidingo. Ngokuqonda ukuthi amakhasimende afunani ngempela, inhlangano ingaqondisa izinsiza zayo kanye nemizamo ekuletheni lokho kanye okungeza inani, kuyilapho inciphisa noma ikhipha izingxenye ezingangezi inani. Le ndlela iqinisekisa ukuthi izinsiza zabiwa ngendlela efanele, okuyingxenye esemqoka yeMigomo Yokukhiqiza Okuncane.

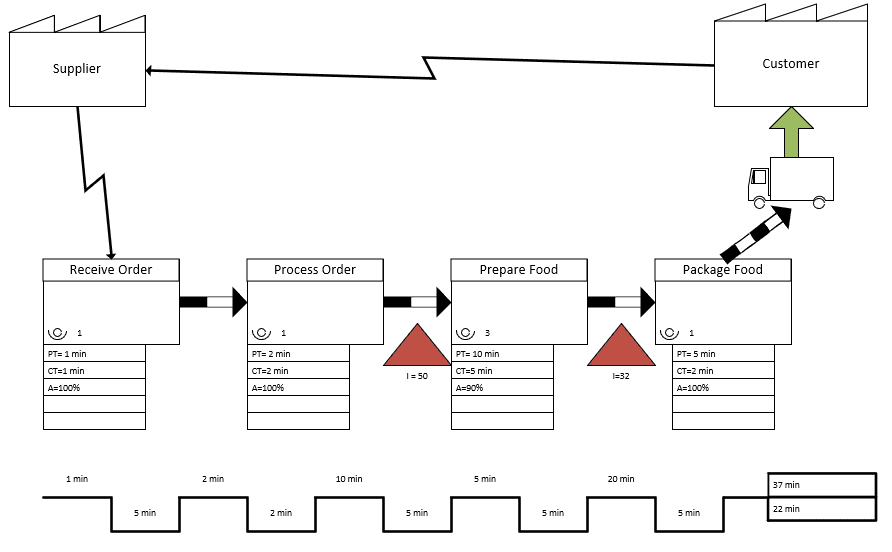

2/ Imephu Yokusakaza Kwenani: Ukubona Ngeso Lengqondo Ukugeleza Komsebenzi

Umgomo wesibili we-Lean, "Value Stream Mapping," udlala indima ebalulekile ekusizeni izinhlangano zibone futhi ziqede ukungcola ezinqubweni zazo.

Ukuhlelwa kwemephu yokusakaza kokusakaza kuhlanganisa ukudala ukumelwa okubonakalayo okuphelele kwayo yonke inqubo, kusukela kumsuka wezinto ezingavuthiwe kuya kumkhiqizo wokugcina noma isevisi enikeziwe. Lokhu kubuka kusiza ekuqondeni ukulandelana kwemisebenzi ehilelekile kule nqubo.

Ukuhlelwa kwemephu yokusakaza-bukhoma kuyithuluzi elibalulekile lokuhlukanisa phakathi kwemisebenzi enikela ngevelu kumkhiqizo noma isevisi naleyo enganikeli. Imisebenzi engangezi inani, evame ukubizwa ngokuthi “i-muda”, ingabandakanya izinhlobo ezahlukene zokumosha, njengokukhiqiza ngokweqile, ukufakwa kwempahla ngokweqile, isikhathi sokulinda, nokucubungula okungadingekile.

Ngokuhlonza bese ziqeda le mithombo yemfucuza, izinhlangano zingakwazi ukwenza lula izinqubo zazo, zinciphise izikhathi zokuhola, futhi zithuthukise ukusebenza kahle okuphelele.

Nasi isibonelo se-Value Stream Mapping, engakusiza ukuqonde kangcono:

I-3/ Ukugeleza: Ukuqinisekisa Ukuthuthuka Okungenamthungo

"Ukugeleza" kuhloswe ukudala ukuhamba kahle nokuqhubekayo komsebenzi ngaphakathi kwenhlangano. Umqondo wokugeleza ugcizelela ukuthi umsebenzi kufanele usuke kwesinye isigaba uye kwesinye ngaphandle kokuphazamiseka noma ukuphazamiseka, ekugcineni ukhuthaze ukusebenza kahle.

Ngokombono wenhlangano, uLean ukhuthaza ukusungula indawo yokusebenza lapho imisebenzi nemisebenzi kuqhubeka ngaphandle kwesithiyo noma ukubambezeleka.

Cabangela umugqa wokuhlanganisa wokukhiqiza njengesibonelo sokuzuza "ukugeleza." Isiteshi ngasinye senza umsebenzi othile futhi imikhiqizo ihamba kalula isuka kwesinye isiteshi iye kwesinye ngaphandle kokuphazamiseka. Lokhu kukhombisa umqondo we-Flow in Lean.

4/ Isistimu Yokudonsa: Ukuphendula Isidingo

I-Pull System imayelana nokukhiqiza noma ukuletha izinsiza ngokuphendula kuma-oda wamakhasimende. Izinhlangano ezamukela i-Pull System azenzi izinto ngokusekelwe ekuqageleni kwesidingo sesikhathi esizayo. Kunalokho, basabela kuma-oda wangempela atholiwe. Lo mkhuba unciphisa ukukhiqiza ngokweqile, okunye izinhlobo eziyisikhombisa ezinkulu zemfucuza ekukhiqizeni i-Lean.

- Isibonelo sesistimu yokudonsa yisuphamakethe. Amakhasimende adonsa imikhiqizo ayidingayo emashalofini, futhi isitolo esikhulu sigcina amashalofu njengoba kudingeka. Lolu hlelo luqinisekisa ukuthi kuhlale kunempahla eyanele ukuhlangabezana nesidingo samakhasimende, kodwa futhi akukho ukukhiqiza ngokweqile.

- Esinye isibonelo sesistimu yokudonsa indawo yokuthengisa izimoto. Amakhasimende adonsela izimoto athanda kuzo endaweni futhi aziyise kohlolwa. Umdayisi u-oda kuphela izimoto ezintsha kumenzi njengoba kudingeka ukuze kuhlangatshezwane nezidingo zamakhasimende.

5/ Ukuthuthukiswa Okuqhubekayo (Kaizen)

Isimiso sesihlanu nesokugcina se-Lean sithi "Intuthuko Eqhubekayo," eyaziwa ngokuthi "i-Kaizen" noma Inqubo yokuthuthukisa eqhubekayo ye-Kaizen. Imayelana nokugqugquzela isiko lokuthuthuka okuqhubekayo.

Kubandakanya ukwenza ukuthuthuka okuncane, okungaguquki ngokuhamba kwesikhathi kunokwenza izinguquko ezinkulu noma ezinkulu. Lokhu kuthuthukiswa okuncane kuyahlanganisa, okuholela ekuthuthukisweni okuphawulekayo kwenqubo, ikhwalithi, nokusebenza kahle kukonke.

Esinye sezici ezibalulekile zeKaizen ubunjalo bayo obuphelele. Ikhuthaza ukubamba iqhaza kuwo wonke amazinga enhlangano, ivumela abasebenzi ukuthi banikele ngemibono yabo, abakuqaphelile, kanye nemininingwane. Le ndlela yokufundisa ayigcini nje ngokuthuthukisa amakhono okuxazulula izinkinga kodwa futhi yandisa isimilo nokuzibandakanya kwabasebenzi.

I-Kaizen iqinisekisa ukuthi inhlangano igqugquzelwa ngokuqhubekayo ukuze ibe ngcono, isebenze kahle, futhi iphumelele kakhudlwana. Kuwukuzibophezela ekwenzeni ngcono okuqhubekayo futhi kuyisici esibalulekile sesiko Lean.

Imicabango Final

Izimiso Ezi-5 Zokukhiqiza Okuncane: Inani, Imephu Yokusakaza Kwenani, Ukugeleza, Uhlelo Lokudonsa, Nokuthuthukiswa Okuqhubekayo (i-Kaizen) - ihlinzeka izinhlangano ngohlaka olunamandla lokuzuza ukusebenza kahle kakhulu.

Izinhlangano ezamukela i-L5 Principles Of Lean Manufacturing azithuthukisi nje kuphela ukusebenza kahle kwazo kodwa futhi zehlisa ukungcola futhi zithuthukise ikhwalithi yemikhiqizo namasevisi azo.

Imibuzo Evame Ukubuzwa Ngezimiso Zokukhiqiza I-Lean

Yiziphi izimiso ezi-5 zokukhiqiza okuthambile?

Izimiso ezi-5 Zokukhiqiza Okuncane Ivelu, Imephu Yokusakaza Kwevelu, Ukugeleza, Uhlelo Lokudonsa, Nokuthuthukiswa Okuqhubekayo (Kaizen).

Ingabe ikhona imigomo emi-5 noma engu-7?

Nakuba kukhona ukutolika okuhlukile, izimiso ze-Lean ezaziwa kakhulu yilezi ezi-5 ezishiwo ngenhla.

Yimiphi imithetho eyi-10 yokukhiqiza okuthambile?

Imithetho eyi-10 ye-Lean Production ngokuvamile ayiyona isethi evamile ekukhiqizeni okuqinile. Izimiso ezithambile ngokuvamile zisekelwe ezimisweni ezingu-5 ezishiwo ngaphambili. Eminye imithombo ingase ibhale “imithetho,” kodwa akuvunyelwananga ngayo yonke indawo.

Ref: I-ASCM | Ukukhiqiza