In the dynamic landscape of modern business, organizations are constantly seeking ways to enhance efficiency, reduce defects, and optimize processes. One powerful methodology that has proven to be a game-changer is the 6 Sigma DMAIC (Define, Measure, Analyze, Improve, Control) approach. In this blog post, we'll delve into the 6 Sigma DMAIC, exploring its origins, key principles, and transformative impact on various industries.

Table Of Contents

- What Is The 6 Sigma DMAIC Methodology?

- Breaking Down the 6 Sigma DMAIC Methodology

- Applications of 6 Sigma DMAIC in Various Industries

- Challenges and Future Trends Of 6 Sigma DMAIC

- Final Thoughts

- FAQs

What Is The 6 Sigma DMAIC Methodology?

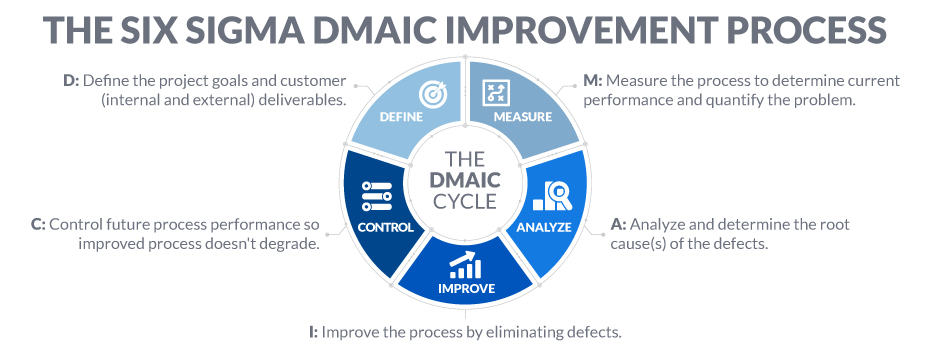

The acronym DMAIC represents five stages, namely Define, Measure, Analyze, Improve, and Control. It's the core framework of the Six Sigma methodology, a data-driven approach aimed at process improvement and variation reduction. The DMAIC process of 6 Sigma uses statistical analysis and structured problem-solving to achieve results that can be measured and sustained.

Related: What Is Six Sigma?

Breaking Down the 6 Sigma DMAIC Methodology

1. Define: Setting the Foundation

The first step in the DMAIC process is to clearly define the problem and the project goals. This involves

- Identifying the process that needs improvement

- Understanding customer requirements

- Establishing specific

- Measurable objectives.

2. Measure: Quantifying the Current State

Once the project is defined, the next step is to measure the existing process. This involves

- Collecting data to understand the current performance

- Identifying key metrics

- Establishing a baseline for improvement.

3. Analyze: Identifying Root Causes

With data in hand, the analysis phase focuses on identifying the root causes of the issues. Statistical tools and techniques are employed to uncover patterns, trends, and areas where improvement is needed.

4. Improve: Implementing Solutions

Armed with a deep understanding of the problem, the Improve phase is about generating and implementing solutions. This may involve

- Redesigning processes,

- Introducing new technologies,

- Or making organizational changes to address the root causes identified in the Analyze phase.

5. Control: Sustaining the Gains

The final phase of DMAIC is Control, which involves implementing measures to ensure the improvements are sustained over time. This includes

- Developing control plans,

- Setting up monitoring systems,

- And providing ongoing training to maintain the enhanced process.

Applications of 6 Sigma DMAIC in Various Industries

6 Sigma DMAIC is a powerful methodology with wide-ranging applications across industries. Here's a snapshot of how organizations use DMAIC to drive excellence:

Manufacturing:

- Reducing defects in production processes.

- Enhancing product quality and consistency.

Healthcare:

- Improving patient care processes and outcomes.

- Minimizing errors in medical procedures.

Finance:

- Enhancing accuracy in financial reporting.

- Streamlining financial transaction processes.

Technology:

- Optimizing software development and hardware manufacturing.

- Improving project management for timely deliveries.

Service Industry:

- Enhancing customer service processes for quicker issue resolution.

- Optimizing supply chain and logistics.

Small and Medium-sized Enterprises (SMEs):

- Implementing cost-effective process improvements.

- Enhancing product or service quality with limited resources.

6 Sigma DMAIC proves valuable in streamlining operations, reducing costs, and ensuring consistent quality, making it a go-to methodology for organizations striving for continuous improvement.

Challenges and Future Trends Of 6 Sigma DMAIC

While Six Sigma DMAIC has proven its effectiveness, it's not without its challenges.

Challenges:

- Gaining buy-in from leadership: 6 Sigma DMAIC requires buy-in from leadership in order to be successful. If leadership is not committed to the project, it is unlikely to be successful.

- Cultural resistance: 6 Sigma DMAIC can be difficult to implement in organizations with a culture of resistance to change.

- Lack of training and resources: DMAIC 6 Sigma requires a significant investment of resources, including the time of employees, as well as the cost of training and software.

- Sustainability: It can be difficult to sustain the improvements made through Six Sigma DMAIC after the project is completed.

Future Trends

Looking ahead, the integration of technology, artificial intelligence, and big data analytics is expected to play a significant role in enhancing the capabilities of the 6 Sigma DMAIC methodology.

- Technology Integration: Increasing use of AI and analytics for advanced data insights.

- Global Implementation: 6 Sigma DMAIC expanding to diverse industries globally.

- Hybrid Approaches: Integration with emerging methodologies like Agile for a holistic approach.

Navigating these challenges while embracing future trends will be crucial for organizations harnessing the full potential of 6 Sigma DMAIC.

Final Thoughts

The 6 Sigma DMAIC methodology stands as a beacon for organizations for improvement. To amplify its impact, AhaSlides offers a dynamic platform for collaborative problem-solving and data presentation. As we embrace future trends, integrating technologies like AhaSlides into the 6 Sigma DMAIC process can enhance engagement, streamline communication, and drive continuous improvement.

FAQs

What is the Six Sigma DMAIC Methodology?

Six Sigma DMAIC is a structured methodology used for process improvement and variation reduction.

What are the 5 Phases of 6 Sigma?

The 5 phases of Six Sigma are: Define, Measure, Analyze, Improve, and Control (DMAIC).

Ref: 6Sigma